As a professional rubber cable group, Hongliang has many advantages. First, not only is Hongliang a supplier, but also is a manufacturer. You can purchase kabel rubber at a low price, because there is no middlemen to pocket the difference. Secondly, With the development of this years, our company has accumulated a wealth of experience of production of the kabel rubber. You can rest assured that the quality of production. Please feel free to contact us if you have any question.

Rubber Cable Feature:

1. Voltage: 300/750V,0.6/1kv, 6/10kv

2. Conductor: Flexible copper/Tinned copper

3. Conductor type: copper IEC60228-2004 class1,class2,class5 and 6

4. Insulation: Vulcanised Rubber/Rubber/EPR/Silicone Rubber

5. Color of insulation: Red, Yellow, Green, Light blue, White, Black, Grey, Brown, Orange, Violet, Yellow/Gree

6. Nominal cross section area: 0.5~400mm2

7. Cores: single or multi-core

8. Standard: IEC,VDE,DIN etc

9. Packaging: Iron Or Wooden Drum or according to your requirement

10. Rubber cable type: H05RR-F,H07RN-F,H07ZZ-F,H01N2-D,NSHXAFO,NSGAFOU,H07N8-F/ ,mining rubber cable.

| silicone rubber cable | Get Quote | |

| 2/3/4/5 core rubber flex cable | Get Quote |

What’s the structure of rubber cable?

First, you should adopt soft copper conductor of rubber power cable. The bending and torsion of the whole cable is also affected by the insulation and sheathed structure. Secondly, Insulation of rubber mains cable requires adequate electrical insulation performance. Adopt good rubber and extruded rubber technology. The thickness of insulation is thicker than that of general rubber sheathed cables. Thirdly, the shielding layer of rubber mains cable. If semi-conductive rubber is used as shielding layer, its transition resistance should meet the standard requirement. In order to ensure the relay protection system in the accident state of reliable operation. Fourthly, cable structure. You should use smaller pitch multiples to improve the flexibility of the rubber cable. Fifthly, the sheath of rubber wire. Adequate mechanical strength and good wear resistance is necessary for sheath.

The overview of rubber cable

Rubber cable is a flexible and movable cable with multiple strands of copper wire as conductors, and covered by rubber insulation and sheath. Rubber cable has a broad use in a variety of electrical equipment, such as household appliances, electric machinery. In the meantime, you can use rubber wire in indoor or outdoor environment. According to the mechanical force of the rubber mains cable, the product structure is divided into light, medium and heavy. There is also a proper connection in the section. Generally speaking, light rubber covered cable used in daily appliances, small electric equipment. Softness, lightness and good bending performance are basic requirements of light rubber cable. Medium rubber wire, except for industrial use, it has a wide use in agricultural electrification.

In port machinery and searchlight can use heavy duty rubber flex cable. There are many kinds of rubber cable, most of which are electric wire and cable for electric equipment. It has a wide range of use, varieties and large production. According to the different application of rubber power cable, it can be divided into the following categories: general rubber cable, general rubber insulated flexible cable, mining sets of soft rubber wire, rubber jacket cable, and marine cable, etc. The common rubber cable include general rubber flexible cable, rubber jacket cable, mining sets of soft rubber cable, welding cable and so on.

The general rubber insulated flexible cable

The general rubber insulated flexible cable has a wide use in industry, agriculture and daily electricity as a mobile power line connecting electrical devices. You can use it in various outdoor and outdoor environments. According to the external force condition, this cable has two form: medium rubber wire and heavy duty rubber cable. The medium rubber cable is so flexible that it can move and bend. It’s weight is light and outer diameter is small. It’s convenient to use and generally unable to bear external force. Heavy duty rubber wire can withstand large mechanical external forces. The sheathing has high mechanical properties, good wear resistance and elasticity. At the same time, it has also certain softness for bending and moving. The general rubber insulated flexible cable moves frequently and is often subjected to mechanical forces in the process of using, such as bending, torsion, and friction. So it should be soft and wear – resistant. Rubber cable for outdoor use should also withstand sunlight. So this kind of cable is also required to be sun-aging and oil-resistant and moisture-proof.

The mining sets of soft rubber cable

The mining sets of soft rubber wire has a broad application in coal mine and other mines. There are a lot of combustible substances in mine wells. Such as gas and dust. The cable moves frequently and is often suffer from mechanical forces in the process of using, such as bending, torsion, and friction. Therefore, the requirements for mining sets of soft rubber cables are particularly strict. The conductor core should have a high flexibility. The insulation layer shall have high electrical and mechanical strength. The mining sets of soft rubber wire must be soft, wear-resistant and impact resistant. Meanwhile, it can bend frequently and have good flame-retardant properties. The sheath of cable is much thicker than that of other cables, so as to increase the impact and pressure of the cable.

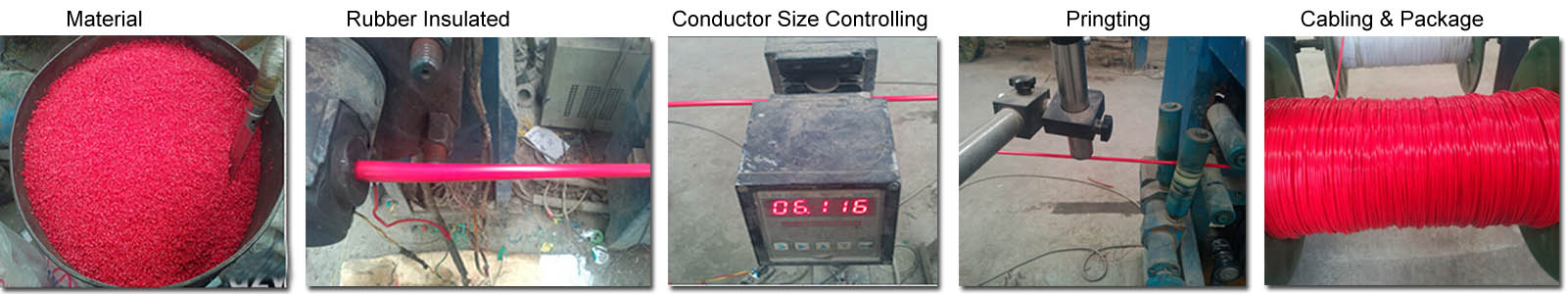

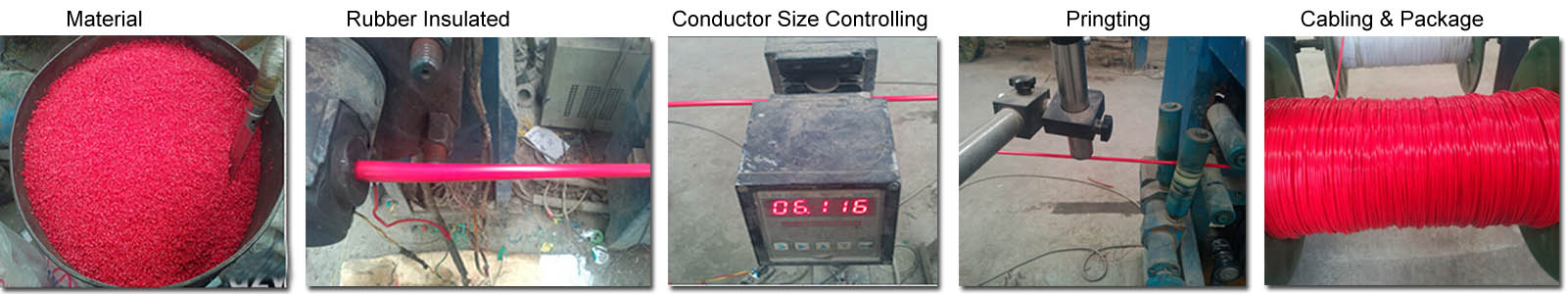

Rubber cable’ s production process

Packaging&Delivery: Before shipment every types of cables have been rigorously tested.

Customer Case: We have exported wires and cables to more than 30 countries, such as: Russian, America, Yemen, South America, North America, Middle East, Africa, Asia, Oceania countries etc.