1 awg welding cable Construction

1. Conductor : Flexible bare annealed copper wire or tinned copper wire

2. Insulation: PVC or Rubber Material or EPR

3. Sheath: Natural rubber, Horoprene rubber or other syntheitic rubber,PVC or or CSP.

4. No.Cross-section: 10mm2, 16mm2, 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120m2, 150mm2, 185mm2 , 240mm2.

5. AWG: 6, 4, 2, 1, 1/0, 2/0, 3/0, 4/0, 250, 350, 500

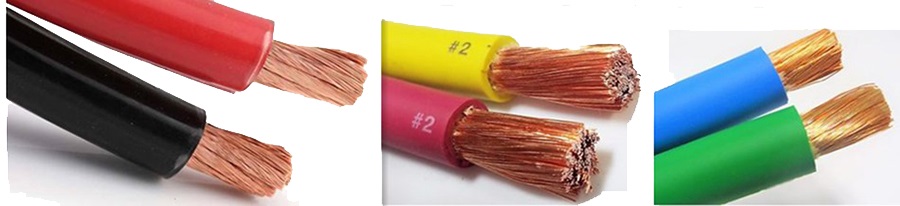

6. Color: Choice of Black, Orange, Red or Yellow Blue jacket, single & double insulated.

Why choose Hongliang?

Hongliang Cable Group is a professional 1 awg welding cable manufacturer and supplier from China. Our company is a collection of scientific research, industry, trade as one of the group shareholding enterprises. You can enjoy the excellent service, but above all, you can get superb a 1 awg welding cable at a competitive price. And we always obey our business principle that “Quality First, Clients First”.

The way of 1 awg welding cable fault location

First of all, determine the property of the fault of 1 gauge welding wire. According to the phenomenon when the fault occurs and some simple tests to judge property of the fault preliminarily. You should know the fault resistance is high or low, flash over or closed fault. By preliminary judgement, you can not determine the property of fault of 1 gauge welding cable completely. So you must measure the insulation resistance and carry out the conduction test. Secondly, burn-through of fault point of 1 gauge welding cable. That is to say, turn a high or flash over fault into a low resistance fault by burn-out for rough measurement. Last, loose measure. Namely, use the instrument to measure the fault distance on one side of the 1 gauge welding wire. In addition, calculate the location of the fault point using the cable line technical data.

Precautions for operation of 1 awg welding cable

Do not overload or overheat for a long time. Therefore, you shouldn’t ignore the monitoring of 1 gauge welding cable load current and external temperature. You should pay special attention to the operation and inspection of direct-buried 1 gauge welding wire. The ground near the 1 gauge welding cable cannot be excavated casually. The scale heavy objects and corrosive substances must not place the ground in the vicinity of the 1 gauge welding wire path. In addition, don’t move cable path markers and protective devices optionally. After the feeder tripping of the 1 gauge welding cable line, don’t forget the inspection of cable. And focus on whether the 1 gauge welding wire path is excavated and damaged. If you want returned to service, it is necessary to retest the 1 awg welding cable. Hongliang Cable Group reminds you that must be careful to use cables.

Our advantage: Hongliang Cable Group is one of the most high-quality cable manufacturers and suppliers in China. Our cable for sale absolutely is superior. We can manufacturer quality and cheap cable. So for the quality of cable, you can be assured of it. You can send us an e-mail or call at any time.

Customer Case: We have exported wires and cables to more than 30 countries, such as: Russian, America, Yemen, South America, North America, Middle East, Africa, Asia, Oceania countries etc.

Hongliang Cable Group welcomes your come and visit our factory at any time. And if you need 1 awg welding cable please contact us.