RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU Cable Design Features

Conductor:Bare electrolytic copper conductor, finely stranded, class 5. Earth conductor made of bare electrolytic copper, extremely finely stranded, class FS (better than class 5).

Insulation:PROTOLON MS

High grade insulation compound based on EPR (at least 3GI3); improved mechanical and electrical performance. Alternative for control cables: ETFE.

Core identification:Light colored compound with black number prints, earth yellow-green.

Core arrangement:Up to 10²mm: 4-core design; From 16²mm: 3-energy cores and splitted earth conductor into three parts.

Screen:Braid screen made of tinned copper wires. Surface covered >80%, transfer impedance<100mOhm/m at <= 30MHz

Inner sheath:Special compound based on EPR (at least GM1b); color: black

Outer sheath:High grade compound based on EVA with excellent abrasion and aging performances. Color: black.

Marking:RONDOFLEX (CHAIN) (N)GRDGOEU (number of cores)x(cross section) 0,6/1 kV

RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU Cable Electrical Parameters

Rated voltage:0.6/1 kV (600/1000V) Max. permissible operating voltage AC:0.7/1.2 kV

Max. permissible operating voltage DC:0.9/1.8 kV

AC Test Voltage:3.5 kV (5 Min.)

EMC:Given thanks to the special cable design Current Carrying Capacity description:According to DIN VDE 0298, Part 4:

-single cores: table 15-section 2;

-multi cores: table 15-section 4.

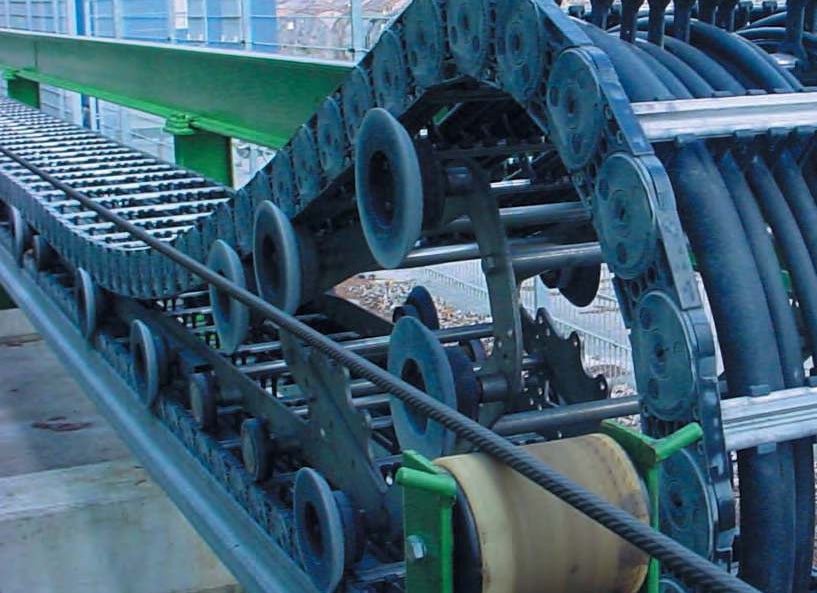

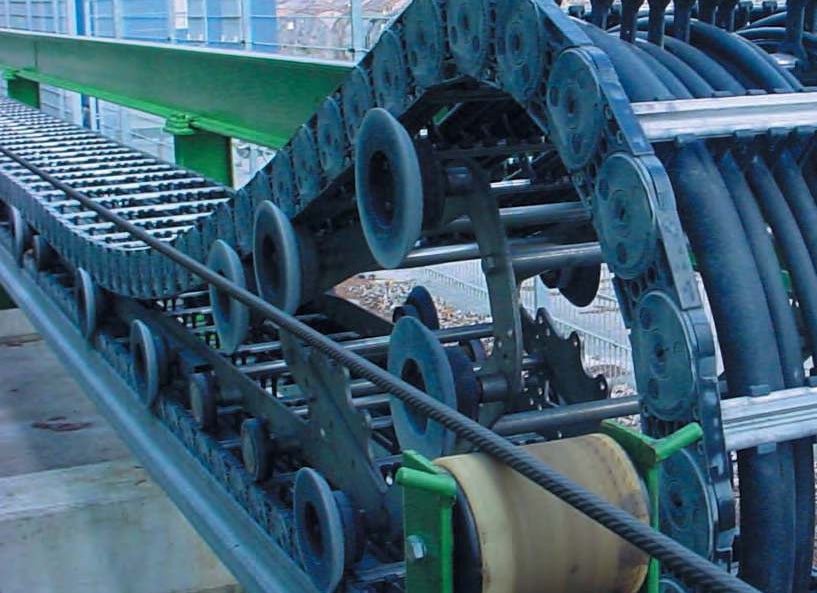

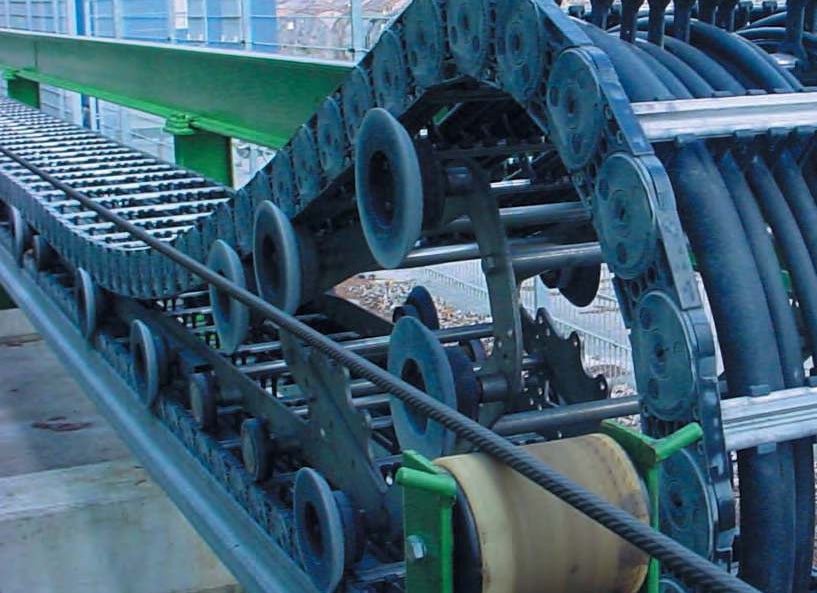

RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU Cable Application

Applicable in all chain systems (e.g. container cranes, stacking cranes, indoor cranes, material handling equipment). Especially suitable in applications where, due to the outdoor installation, long travel distances or high travel speed, high performances are expected from the cable (such as long lifetime, full reliability, resistance to abrasion, etc.)

RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU Cable Spec

Number of cores x cross sectionConductor diameter max. mmOuter diameter min. mmOuter diameter max. mmBending radius free moving min. mmWeight (ca.) kg/kmPermissible tensile force max. NConductor resis- tance at 20°C max.Current carrying capacity (1)Short Circuit Current (conduc- tor)

| (N)GRDGOEU-O power cables, single-core design | |||||||||

| 1×16 | 5.7 | 7.6 | 9.7 | 39 | 210 | 240 | 1.21 | 99 | 2.29 |

| 1×25 | 7.1 | 10.2 | 12.2 | 61 | 330 | 370 | 0.78 | 131 | 3.58 |

| 1×35 | 8.3 | 12.1 | 14.1 | 71 | 445 | 520 | 0.55 | 162 | 5.01 |

| 1×50 | 9.8 | 13.9 | 15.9 | 80 | 620 | 750 | 0.39 | 202 | 7.15 |

| 1×70 | 11.6 | 15.8 | 17.9 | 90 | 830 | 1050 | 0.27 | 250 | 10.01 |

| 1×95 | 13.8 | 19.1 | 21.1 | 106 | 1120 | 1420 | 0.21 | 301 | 13.59 |

| 1×120 | 14.9 | 20.8 | 22.8 | 114 | 1390 | 1800 | 0.16 | 352 | 17.16 |

| 1×150 | 17.2 | 23 | 26 | 130 | 1740 | 2250 | 0.13 | 404 | 21.45 |

| 1×185 | 18 | 25.2 | 28.2 | 141 | 2090 | 2770 | 0.11 | 461 | 26.46 |

| 1×240 | 22.5 | 29.9 | 32.9 | 165 | 2830 | 3600 | 0.08 | 540 | 34.32 |

| (N)GRDGCGOEU-O screened power cables, single-core design | |||||||||

| 1x16C | 5.7 | 10.1 | 12.1 | 61 | 320 | 240 | 1.21 | 99 | 2.29 |

| 1x25C | 7.1 | 12.8 | 14.8 | 74 | 450 | 370 | 0.78 | 131 | 3.58 |

| 1x35C | 8.3 | 13.7 | 15.7 | 79 | 540 | 520 | 0.55 | 162 | 5.01 |

| 1x50C | 9.8 | 15.7 | 17.7 | 89 | 740 | 750 | 0.39 | 202 | 7.15 |

| 1x70C | 11.6 | 18.7 | 20.7 | 104 | 1020 | 1050 | 0.27 | 250 | 10.01 |

| 1x95C | 13.8 | 20.8 | 22.8 | 114 | 1260 | 1420 | 0.21 | 301 | 13.59 |

| 1x120C | 14.9 | 22.8 | 24.8 | 124 | 1580 | 1800 | 0.16 | 352 | 17.16 |

| 1x150C | 17.2 | 25.6 | 28.6 | 143 | 2000 | 2250 | 0.13 | 404 | 21.45 |

| 1x185C | 18 | 27.7 | 30.7 | 154 | 2370 | 2770 | 0.11 | 461 | 26.46 |

| 1x240C | 22.5 | 31.9 | 34.9 | 175 | 3130 | 3600 | 0.08 | 540 | 34.32 |

| (N)GRDGOEU-J multicore power cables | |||||||||

| 4×2,5 | 2 | 9.9 | 11.5 | 46 | 200 | 150 | 7.98 | 30 | 0.36 |

| 4×4 | 2.9 | 12.7 | 14.7 | 74 | 320 | 240 | 4.95 | 41 | 0.57 |

| 4×6 | 3.6 | 14.2 | 16.2 | 81 | 430 | 360 | 3.3 | 53 | 0.86 |

| 4×10 | 4.6 | 16.7 | 18.7 | 94 | 670 | 600 | 1.91 | 74 | 1.43 |

| 4×16 | 5.9 | 21.2 | 23.2 | 116 | 1020 | 960 | 1.21 | 99 | 2.29 |

| 4×25 | 7.2 | 26.5 | 29.5 | 148 | 1600 | 1500 | 0.78 | 131 | 3.58 |

| 3×35+3×16/3 | 8.1 | 26.4 | 29.4 | 147 | 1770 | 1570 | 0.55 | 162 | 5.01 |

| 3×50+3×25/3 | 10 | 31.5 | 34.5 | 173 | 2560 | 2250 | 0.39 | 202 | 7.15 |

| 3×70+3×35/3 | 11.9 | 37.6 | 40.6 | 203 | 3550 | 3150 | 0.27 | 250 | 10.01 |

| 5×6 | 3.6 | 15.8 | 17.8 | 89 | 530 | 450 | 3.3 | 53 | 0.86 |

| 5×10 | 4.6 | 19.7 | 21.7 | 109 | 850 | 750 | 1.91 | 74 | 1.43 |

| 5×16 | 5.9 | 23.4 | 25.4 | 127 | 1300 | 1200 | 1.21 | 99 | 2.29 |

| (N)GRDGCGOEU-J multicore power cables, overall screened | |||||||||

| 4×2,5C | 1.9 | 11.2 | 13.2 | 66 | 310 | 150 | 7.98 | 30 | 0.36 |

| 4x4C | 2.9 | 15.2 | 17.2 | 86 | 490 | 240 | 4.95 | 41 | 0.57 |

| 4x6C | 3.6 | 17 | 19 | 95 | 650 | 360 | 3.3 | 53 | 0.86 |

| 4x10C | 4.6 | 19.2 | 21.2 | 106 | 870 | 600 | 1.91 | 74 | 1.43 |

| 3×16+3×2,5C | 5.9 | 20.3 | 22.3 | 112 | 1050 | 720 | 1.21 | 99 | 2.29 |

| 3×25+3x4C | 7.2 | 25.7 | 28.7 | 144 | 1610 | 1120 | 0.78 | 131 | 3.58 |

| 3×35+3x6C | 8.1 | 28.4 | 31.4 | 157 | 2140 | 1570 | 0.55 | 162 | 5.01 |

| 3×50+3×25/3 | 10 | 34.9 | 37.9 | 190 | 3080 | 2250 | 0.39 | 202 | 7.15 |

| 3×70+3×35/3 | 11.8 | 39.8 | 42.8 | 214 | 4090 | 3150 | 0.27 | 250 | 10.01 |

| 3×95+3×50/3 | 13.8 | 43.7 | 46.7 | 234 | 5080 | 4270 | 0.21 | 301 | 13.59 |

| 5x16C | 5.9 | 25.7 | 28.7 | 144 | 1630 | 1200 | 1.21 | 99 | 2.29 |

| (N)GRDGOEU-J control cables | |||||||||

| 12×1,5 | 1.5 | 11.7 | 13.7 | 69 | 305 | 270 | 13.3 | 23 | 0.21 |

| 24×1,5 | 1.5 | 19.9 | 21.9 | 110 | 710 | 540 | 13.3 | 23 | 0.21 |

| 7×2,5 | 1.9 | 11.3 | 13.3 | 67 | 290 | 260 | 7.98 | 30 | 0.36 |

| 12×2,5 | 1.9 | 15.3 | 17.4 | 87 | 490 | 450 | 7.98 | 30 | 0.36 |

| 18×2,5 | 1.9 | 19.5 | 21.5 | 108 | 760 | 670 | 7.98 | 30 | 0.36 |

| 24×2,5 | 1.9 | 22.5 | 24.5 | 123 | 1020 | 900 | 7.98 | 30 | 0.36 |

| (N)GRDGOEU-J overall screened control cables | |||||||||

| 12×1,5C | 1.5 | 14.6 | 16.6 | 83 | 490 | 180 | 7.98 | 23 | 0.36 |

| 5×2,5C | 1.9 | 12.7 | 14.7 | 74 | 435 | 270 | 13.3 | 30 | 0.21 |

| (N)GRDGOEU-O bus cables | |||||||||

| 1x(2×0,5)C | 0.9 | 8 | 10 | 40 | 135 | 10 | 39 | 10 | 0.07 |

| (4x2x0,5)C | 0.9 | 17.6 | 19.6 | 98 | 500 | 60 | 39 | 10 | 0.07 |

| 4x(2×0,5)C | 0.9 | 19 | 21 | 105 | 590 | 60 | 39 | 10 | 0.07 |

| 6x(2×0,5)C | 0.9 | 22.2 | 24.2 | 121 | 820 | 90 | 39 | 10 | 0.07 |

| 6x(2×1)C | 1.3 | 26.3 | 29.3 | 147 | 1130 | 180 | 19.5 | 18 | 0.14 |

| Fiber Optic | |||||||||

| 6G62,5/125μ | 12.6 | 14.6 | 73 | 250 | 500 | n. a. | n. a. | n. a. | |

| 12G62,5/125μ | 12.6 | 14.6 | 73 | 250 | 500 | n. a. | n. a. | n. a. | |

| 6E9/125μ | 12.6 | 14.6 | 73 | 250 | 500 | n. a. | n. a. | n. a. | |

| 18G50/125μ | 12.6 | 14.6 | 73 | 250 | 500 | n. a. | n. a. | n. a. | |

| 12G50/125μ | 12.6 | 14.6 | 73 | 250 | 500 | n. a. | n. a. | n. a. | |

| 18G62,5/125μ | 12.6 | 14.6 | 73 | 250 | 500 | n. a. | n. a. | n. a. | |

| 6G50/125μ | 12.6 | 14.6 | 73 | 250 | 500 | n. a. | n. a. | n. a. | |

RONDOFLEX(CHAIN) (N)GRDGOEU Cable Why Choose Hongliang?

Hongliang Cable Group is one of the leading manufacturers of RONDOFLEX(CHAIN) (N)GRDGOEU Cable. We offer a wide variety of reeling cables. Our cables are designed to last for decades and come with a lifetime warranty. Our cables are rigorously tested before they leave the factory, ensuring that every product meets their high standards. Our cables also meet UL and CSA requirements, giving users peace of mind when using any of their products.

When choosing Hongliang Cable Group for your RONDOFLEX(CHAIN) (N)GRDGOEU Cable needs, you can rest assured that you’re getting a product that is built to last. Our products have been tested time and time again and have proven themselves over the years as reliable components in many different applications. On top of that, we offer competitive prices on our products so you can be sure you’re getting a great value as well as quality construction.

Customer Case: We have exported wires and cables to more than 30 countries, such as: Russian, America, Yemen, South America, North America, Middle East, Africa, Asia, Oceania countries etc.