4 gauge welding cable Construction

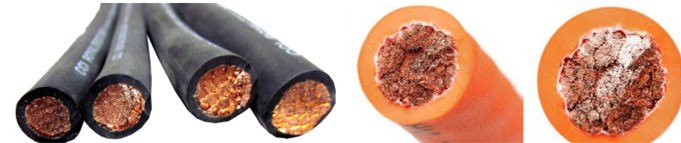

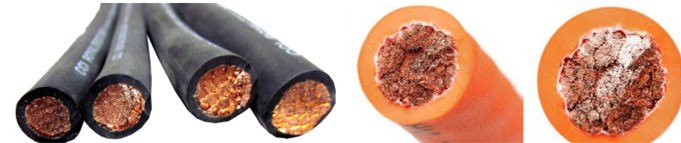

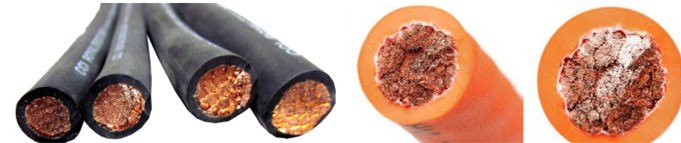

1. Conductor : Flexible bare annealed copper wire or tinned copper wire

2. Insulation: PVC or Rubber Material or EPR

3. Sheath: Natural rubber, Horoprene rubber or other syntheitic rubber,PVC or or CSP.

4. No.Cross-section: 10mm2, 16mm2, 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120m2, 150mm2, 185mm2 , 240mm2.

5. AWG: 8 awg or others

6. Color: Choice of Black, Orange, Red or Yellow Blue jacket, single & double insulated.

Why is the 4 gauge welding cable quality so good of Hongliang?

Strengthening control of raw material quality for 4 gauge welding cable.

Raw materials are the foundation of 4 awg welding cable. If you want to control the quality of products, you must start from the source of production. The quality of copper conductor, aluminum conductor, and cable material directly determines properties of 4 gauge welding wire. As a manufacturer, Hongliang attach great importance to the quality of raw materials all the time. When purchasing raw materials, Hongliang will test their important properties. Such as, checking direct current resistance of copper conductor and mechanical properties of 4 gauge welding cable material. When the raw materials enter the factory, the quality inspection department will inspect the quality of the raw materials. Prevent pursuit of low cost and neglect the quality of raw materials. So rest assured of our 4 gauge welding wire.

Strengthening quality control and technology learning of 4 gauge welding cable

In order to improve the quality of 4 gauge welding cable, Hongliang has been adopting relevant quality control and technical training work. And the production staff have learned the manufacturing and testing standards. We have set up a complete quality management control system. What’s more, we have a corresponding mechanism to solve the problems found in production and manufacture of 4 gauge welding wire. All employees are in strict accordance with the standard production standards and have a strong sense of quality control. From this above, Hongliang have confidence in the quality of 4 gauge welding cable. Please feel free to choose our 4 gauge welding wire.

Strengthening the work of 4 gauge welding cable quality inspection and control

Hongliang pay attention to the routine test sampling, designate and improve the inspection regulations. And examine the semi-finished and finished 4 awg welding cable regularly and orderly. We pay special attention to routine tests and timely rework or repair of unqualified 4 gauge welding cable samples. Strive to early detection of non-qualified 4 gauge welding wire, timely analysis of causes, adjustment of the process and improve management. So unqualified 4 gauge welding cable never go out. Hongliang will through technological innovation, speeding up industrial restructure, improving the quality of cables and industries.

How to find superior 4 gauge welding cable?

Everybody wants to buy high-quality 4 awg welding cable. So choose a right cable company is very important. Hongliang Cable Group is a large-scale, a variety of products, comprehensive economic strength of cable manufacturing enterprises. We not only manufacture 4 awg welding wire, but also manufacture power cable, concentric cable, ABC cable and so on. No matter which product, the quality is guaranteed. Therefore, if you need 4 awg welding cable please send us an e-mail or call us.

Our advantages: Hongliang Cable Group is one of the most high-quality cable manufacturers and suppliers in China. Our cable for sale absolutely is superior. We can manufacturer quality and cheap cable. So for the quality of cable, you can be assured of it. You can send us an e-mail or call at any time.

Customer Case: We have exported wires and cables to more than 30 countries, such as: Russian, America, Yemen, South America, North America, Middle East, Africa, Asia, Oceania countries, etc.