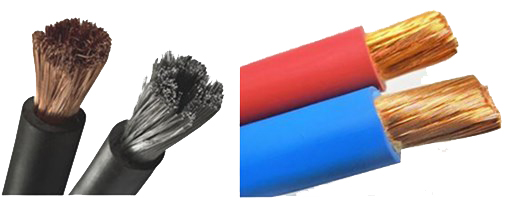

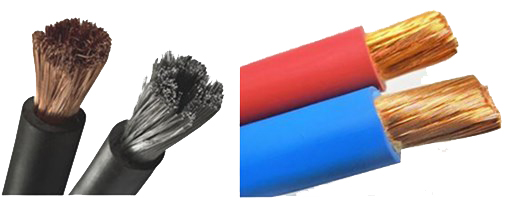

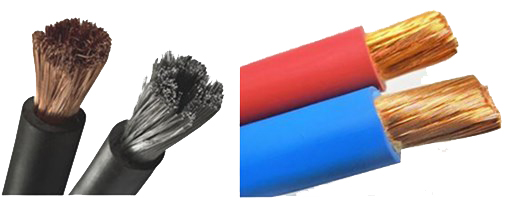

Copper Welding Cable Construction

1. Conductor : Flexible bare annealed copper wire, aluminum, tinned copper wire

2. Insulation: PVC or Rubber Material or EPR

3. Sheath: Natural rubber, Horoprene rubber or other syntheitic rubber,PVC or or CSP.

4. No.Cross-section: 10mm2, 16mm2, 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120m2, 150mm2, 185mm2 , 240mm2.

5. AWG: 6, 4, 2, 1, 1/0, 2/0, 3/0, 4/0, 250, 350, 500

6. Color: Choice of Black, Orange, Red or Yellow Blue jacket, single & double insulated.

What’s the advantage of copper welding wire?

Firstly, low resistivity. The resistivity of aluminium welding cable is about 1.68 times higher than that of copper welding wire. Secondly, good ductility. The elongation rate of copper alloy is 20% to 40%, electrical copper is more than 30%, while that of aluminum alloy is only 18%. Thirdly, high strength. The allowable stress of copper is 70.28% higher than that of aluminum at room temperature. Especially the stress at high temperature, the difference between the two is very far. Fourthly, fatigue resistance. Aluminum conductor of aluminum welding cable is easy to break in repeated bending, but copper is not easy to break. In terms of elasticity, copper welding wire is about 1.7 to 1.8 times higher than aluminium welding cable. Fifthly, large carrying capacity. Because of the low resistivity, the carrying capacity of copper welding wire is about 30% higher than aluminium welding cable in a same area of section.

The other advantages of copper welding wire

Firstly, low voltage loss. Because copper welding wire has a low resistivity, under circumstance of flows through the same current in the same section, it will lower voltage. Therefore, the same transmission distance can guarantee high voltage quality. In other words , the wire can reach far distance under the allowable voltage drop condition. That is to say, the power supply coverage area is large. It is beneficial to the network planning, and reduces the setting of the power supply point. Secondly, low heating temperature. At the same current and section, copper welding wire has much less heat than the aluminum welding cable. And it is safer to operate. Thirdly, low energy consumption. Because copper has a low resistivity, it is obvious that copper welding wire has a low power loss compared to aluminium welding cable. It is beneficial to improving the utilization rate of power generation and protecting the environment.

What’s the advantage of aluminum welding cable?

Firstly, low price. The copper rod price is 3.5 times as much as aluminum rod. So aluminium welding cable is much cheaper than copper welding wire, which is suitable for low-cost engineering or temporary use. You can see it from the copper welding cable price list. Secondly, light in weight. The weight of aluminum welding cable is 40% of copper welding wire, and the cost of construction and transportation is low. Thirdly, anti oxidation and corrosion. Aluminum reacts with oxygen in air to form an oxide film quickly, which prevents further oxidation. Although aluminium welding cable is cheap, copper welding wire has outstanding advantages in power supply, especially underground cable. It has many advantages to use underground copper welding wire. Such as low accident rate, anti corrosion, high reliability, and easy maintenance.

Hongliang Cable Group: HD one of the most excellent copper welding cable manufacturers in China. You can get a reasonable copper welding cable price in our group. Please don’t hesitate to contact us, we can offer a copper welding cable price list for you.

Packaging&Delivery: Before shipment every types of cables have been rigorously tested.

Customer Case: We have exported wires and cables to more than 30 countries, such as: Russian, America, Yemen, South America, North America, Middle East, Africa, Asia,Oceania countries etc.