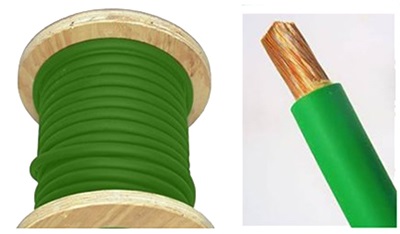

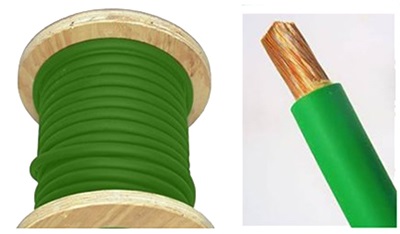

35mm Welding Cable Construction

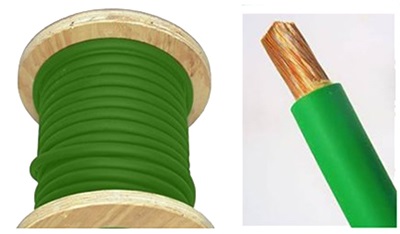

1. Conductor : Flexible bare annealed copper wire or tinned copper wire

2. Insulation: PVC or Rubber Material or EPR

3. Sheath: Natural rubber, Horoprene rubber or other syntheitic rubber,PVC or or CSP.

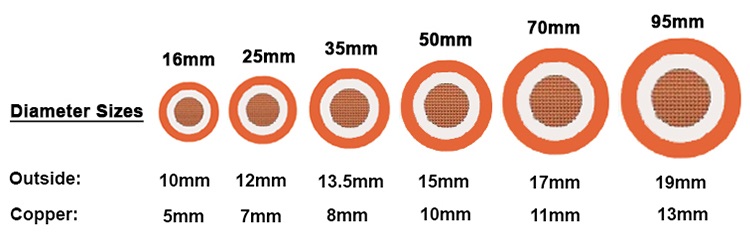

4. No.Cross-section: 10mm2, 16mm2, 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120m2, 150mm2, 185mm2 , 240mm2.

5. AWG: 6, 4, 2, 1, 1/0, 2/0, 3/0, 4/0, 250, 350, 500

6. Color: Choice of Black, Orange, Red or Yellow Blue jacket, single & double insulated.

What should you know when laying welding cable 35mm2?

You should install welding cable 35mm2 from top to bottom. In order to prevent injury and damage to equipment, avoid cross operation. When more than two people to install welding cable 95mm2, you should establish a call response system. Before digging the 95mm welding cable trench, you should know the situation of underground installation. And take measures to prevent damage to underground facilities or electric shock. Before laying 10 mm welding cable, you should set up the cable tray. Pull out the protruding nails from the cable disc to prevent damage when turning. The weight borne by each person shall not exceed 35 kg when manpower is applied to the welding cable 35mm2. All personnel shall stand on the same side of the cable. While, at the corner, they should stand on the outside. When placing 95mm welding cable to the ground, it’s better to lay down in sequence. If you have any question, please contact Hongliang.

The other notes when laying welding cable 35mm2.

The welding cable 95mm2 line should meet the demand of power supply. Ensure the cable line can safe operation, and easy to maintain. For direct buried cables, application of anti-corrosive coating to protect them. The bottom of a direct-buried 95mm welding cable must be flat and free of hard things. Otherwise, there should has a layer of fine sand or soft soil on the bottom of the ditch. At last, cover the concrete protection board. Draw drawings with specific coordinates, positions and directions for maintenance inspection. The depth of the 10 mm welding cable shall be in accordance with the requirements. When laying welding cable 35mm2, you should prevent torsion and bending of the cable. In construction, the turning of the 10 mm welding cable should conform to the bending radius.

Our advantage: Hongliang Cable Group is one of the most high-quality cable manufacturers and suppliers in China. Our cable for sale absolutely is superior. We can manufacturer quality and cheap cable. So for the quality of cable, you can be assured of it. You can send us an e-mail or call at any time.

Customer Case: We have exported wires and cables to more than 30 countries, such as: Russian, America, Yemen, South America, North America, Middle East, Africa, Asia, Oceania countries etc.